連続脱皮炉がアルミ缶リサイクルに革命を起こす

Nov 07, 2023

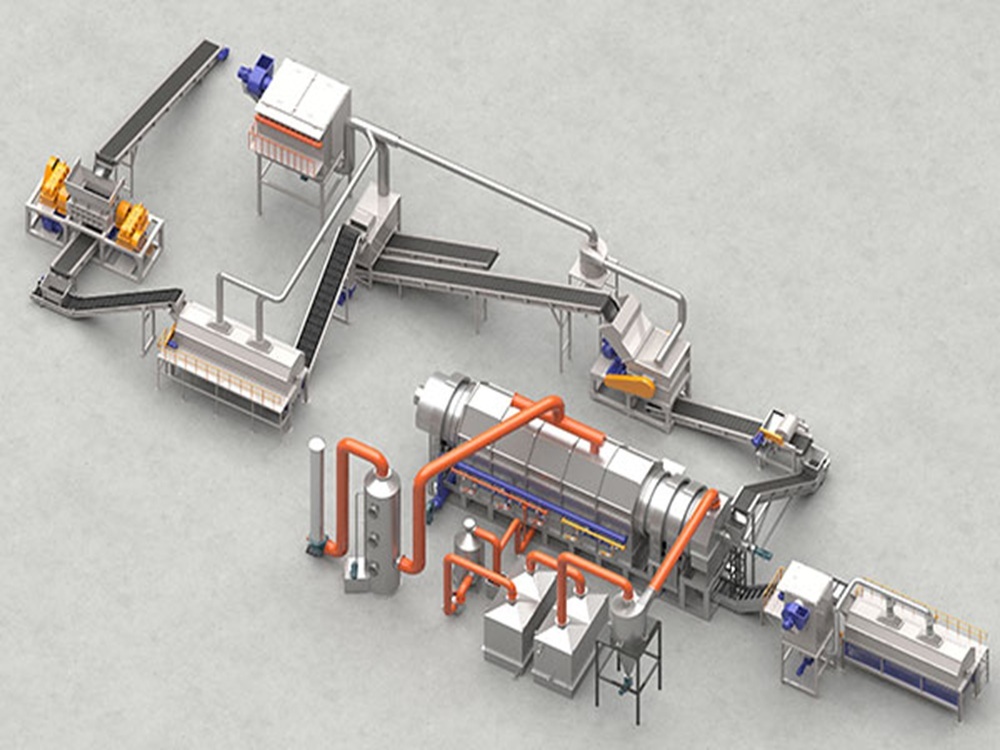

資源循環がますます重要になっている時代において、廃棄アルミ缶を効率的かつ環境に配慮した方法で管理することは重要な課題です。 連続自動炭化炉 これらの缶の脱炭素化と塗装除去プロセスにおいて、極めて重要な役割を果たしています。その仕組みと、それがもたらす大きなメリットについて詳しくご紹介します。 ステージ1:重要な準備段階 リサイクルの旅は準備から始まります。使用済み缶は丸ごと強力な産業用シュレッダーに投入されます。ここで強力な機械力によって、缶はより小さく均一な破片に分解されます。理想的な破片のサイズは3~5cmの間で厳密に制御されます。 この特定のサイズは恣意的なものではありません。アルミニウム片の表面積を最大化し、炭化炉内で均一に熱にさらされるようにするためです。この均一な加熱は、後の工程で効率的かつ完全な塗装除去を行うための基本的な前提条件です。 ステージ2:コアペイント除去プロセス 1. 自動化された整然とした給餌 準備された缶の破片は、自動コンベアシステムを経由して、予熱された連続炭化炉へと搬送されます。この供給プロセスは連続的かつ整然と行われます。供給口には特別に設計されたシール機構が不可欠で、炉内を酸素欠乏または無酸素状態に保ちます。これはプロセスにとって不可欠です。高度な監視システムが供給速度と供給量をリアルタイムで追跡し、スムーズで安定した流れを確保し、詰まりや運転の中断を防止します。 2. 高温炭化と塗装剥離 炉に入れられた破片は、厳密に管理された高温にさらされます。この高温は通常、材質と塗料の種類に合わせて調整された特定の温度範囲に維持されます。この高熱と低酸素環境下で、缶の塗装は変化します。塗料に含まれる有機成分が熱分解して炭化し、層が下層のアルミニウムから剥離します。 同時に、内部の機械システムがゆっくりと回転し、破片を投入口から排出口へと安定して移動させます。この一定の動きにより、すべての破片が均一に処理され、塗装が完全に除去され、きれいな素地のアルミニウムが残ります。 3. 環境・安全管理 低酸素雰囲気の維持は極めて重要です。過剰な酸素はアルミニウムの酸化を引き起こし、品質を低下させ、火災や煙などの安全上の危険につながる可能性があります。炉の高度な設計と精密なガス制御システムにより、この理想的な環境が巧みに維持され、安全で効率的な連続運転を保証します。 ステージ3:環境と経済のメリット 1. クリーンな排出ガス 炭化工程では、分解された塗料やその他の不純物からガスが発生しますが、これらのガスはそのまま放出されるのではなく、専用のガス処理装置によって直ちに回収されます。このシステムは、活性炭吸着や触媒精製といった多段階の浄化プロセスを採用しており、有害物質を除去します。処理されたガスは、国の環境基準を満たすまで浄化された後、安全に放出されるため、周辺環境への影響は最小限に抑えられます。 2. 真の資源回収 塗装除去が成功した後、得られたきれいなアルミニウムは貴重な二次原料となります。このアルミニウムは溶解され、アルミニウムインゴット、シート、あるいは特定の部品といった新たな製品に再鋳造されます。窓枠から自動車部品まで、様々な製品の製造において新たな命を吹き込まれます。 このプロセスは、エネルギー集約型の作業であるバージンアルミニウム鉱石の採掘の必要性を大幅に削減します。エネルギー消費量と生産コストを削減することで、明確な経済的メリットをもたらします。さらに、缶のポイ捨てという環境問題にも効果的に対処し、循環型経済の発展に大きく貢献します。 要約すると、 連続自動炭化炉 アルミ缶リサイクルにおける科学的、高効率、そして環境に配慮したアプローチを実証しています。準備から精製まで、シームレスに統合された工程により、廃缶に新たな命が吹き込まれます。この技術は、資源の保全と環境保護において極めて重要であり、ありふれた廃棄物を貴重な資源へと転換し、より環境に優しい産業活動を支援します。

続きを読む