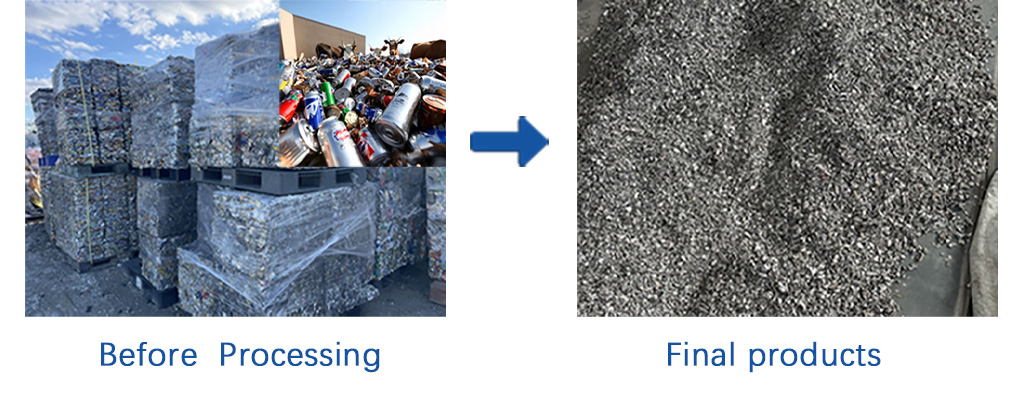

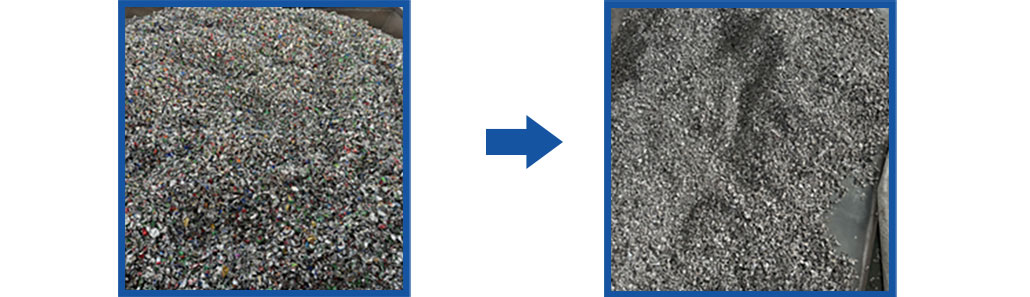

High Performance Scrap Aluminum Cans Decoating Recycling Line

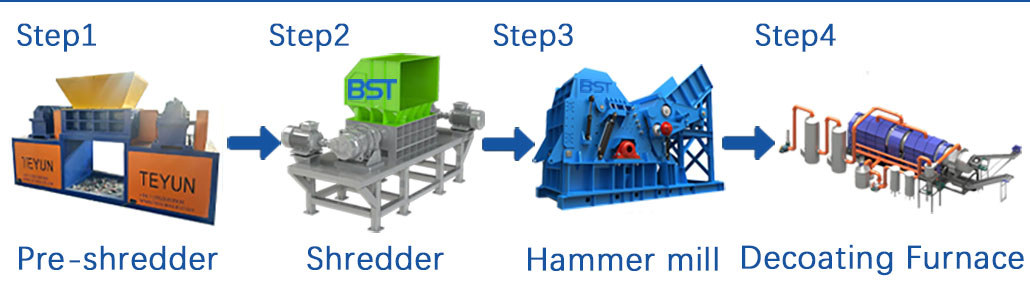

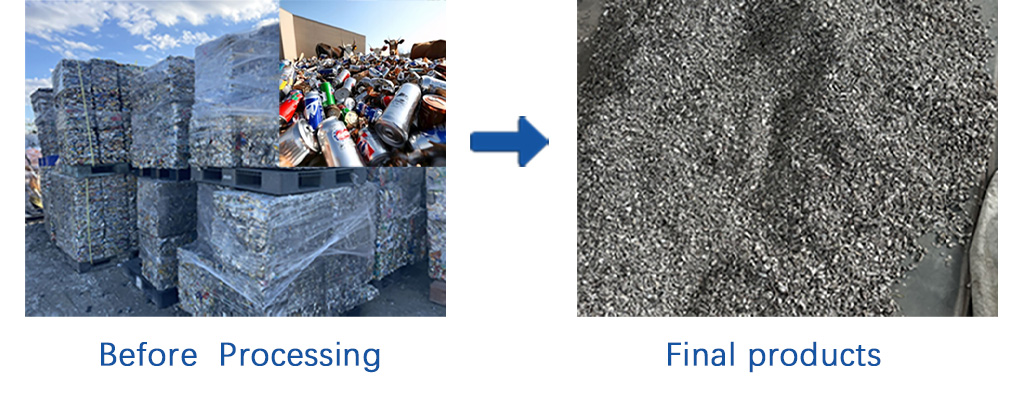

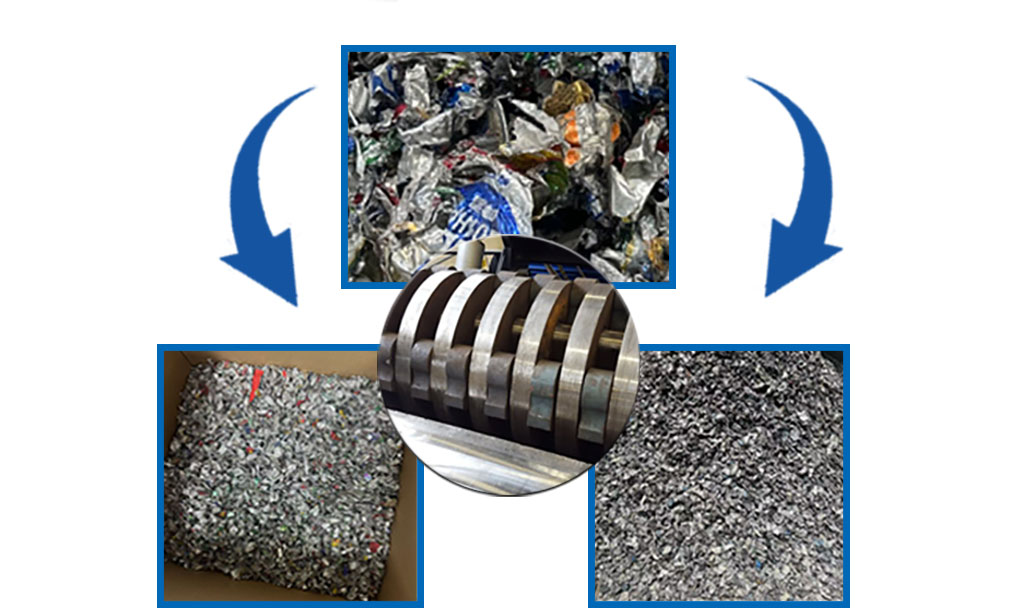

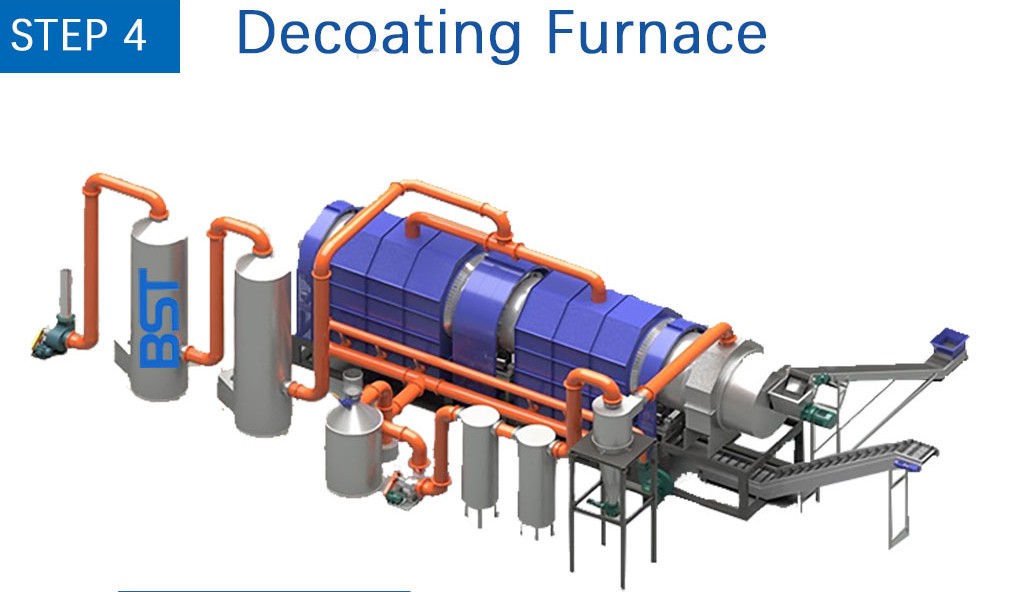

This line is especially designed for the aluminum cans recycling solution. After collecting the scrap aluminum cans( loose or aluminum cans bale) then put them into the shredder and hammer mill to make the big aluminum cans pieces into small size(customized size) pieces; then put the small pieces aluminum cans scrap into the decoating furnace to remove the aluminum cans surface painting. After this process these aluminum cans can be put into melting furnace to melt for further step like aluminum casting ect.

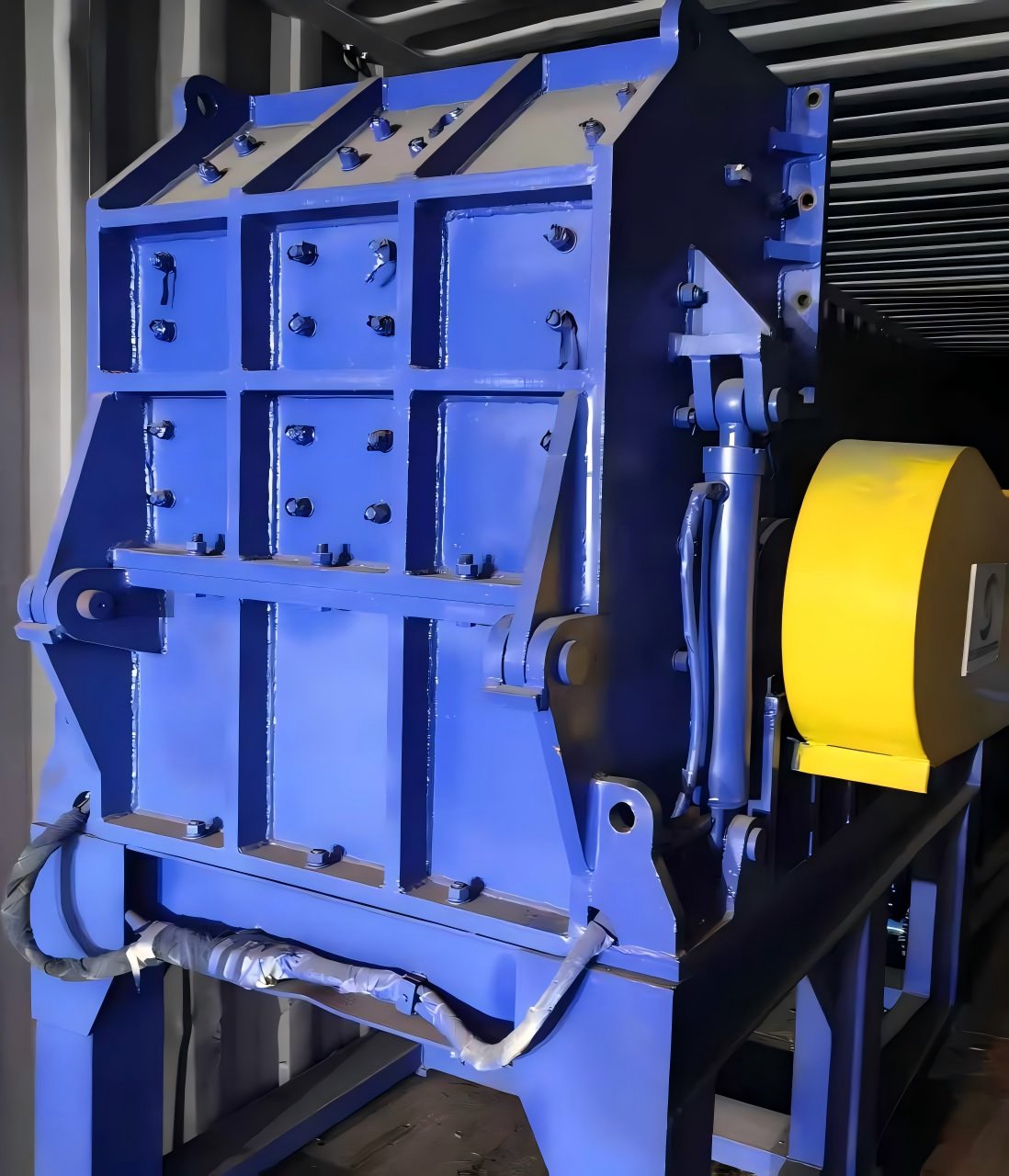

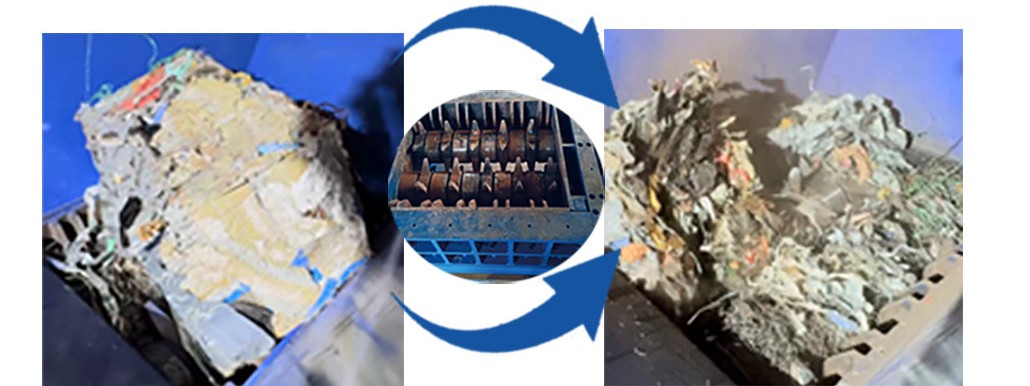

For the step one we use the Pre-shredder, to pre-deal with the bigger size metal scraps which are too big to put into the shredder and big size may broke the shredder. So the pre-shredder main function is to deal with the big size into the small size which suits for the shredder for next step.

--------------占位---------------

It can be frequently reversed, Alloy casting, long service life. H13 shredder blade

High quality burners Second generation dust removal equipment Integrated electrical box

| Model | Best Feeding Temperature | Decoating Time | Processing Capacity (kg/h) |

| TY-1500 | 540℃ | 20-30min | 800 |

| TY-1800 | 540℃ | 20-30min | 1200 |

| TY-2200 | 540℃ | 20-30min | 1500 |

日语

日语 English

English Français

Français Русский

Русский Español

Español Português

Português عربي

عربي