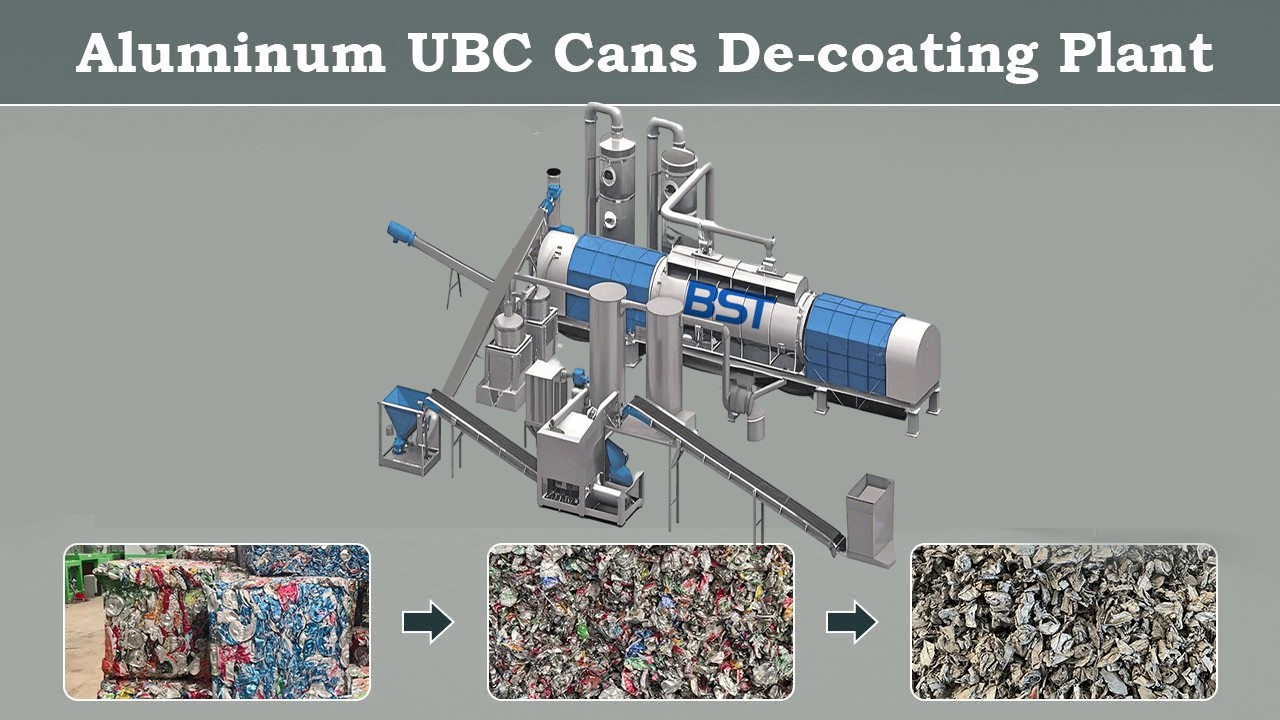

The aluminum cans decoating furnace is vital for high-quality recycling, efficiently removing paint, lacquers, and inks from used beverage cans (UBCs). Here's how it works:

1. Charging: Shredded UBCs are fed into the furnace via a conveyor.

2. Heating & Pyrolysis: The material is heated indirectly (typically to 500-600°C) in a controlled, oxygen-deprived atmosphere. At this temperature, organic coatings thermally decompose (pyrolyze) without melting the aluminum.

3. Volatilization & Combustion: The decomposed organics transform into volatile gases.

4. Gas Treatment: These flammable gases are drawn into a combustion chamber (afterburner), mixed with air, and completely burned off at high temperatures (over 800°C). The resulting hot gases then pass through pollution control systems (like bag filters or scrubbers) to remove particulates and neutralize acids before release.

5. Cooling & Discharge: The decoated, now "clean" aluminum flakes cool sufficiently before exiting the furnace.

The process yields pure aluminum ready for remelting, with minimal emissions and maximum resource recovery.