The Workflow of Tire Recycling Line

May 22, 2024

With billions of used tires generated globally each year, finding sustainable solutions is crucial. Tire recycling offers an environmentally responsible way to manage this waste stream while recovering valuable materials. Here's a simplified overview of the process:

- Pre-processing: Bead wires are removed. Oversized tires are cut.

- Shredding: Tires enter a dual-shaft shredder. Shredded chunks are screened; oversized pieces are returned for further shredding.

- Steel Separation: Sized rubber pieces go through a separator, removing fine steel wire and producing Tire Derived Fuel (TDF).

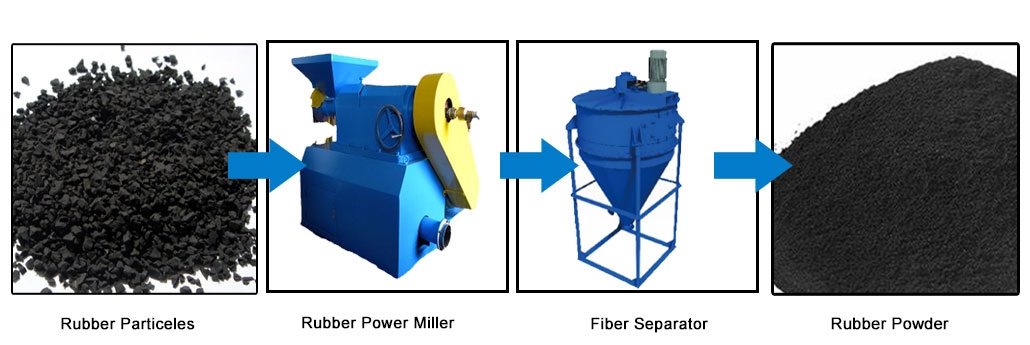

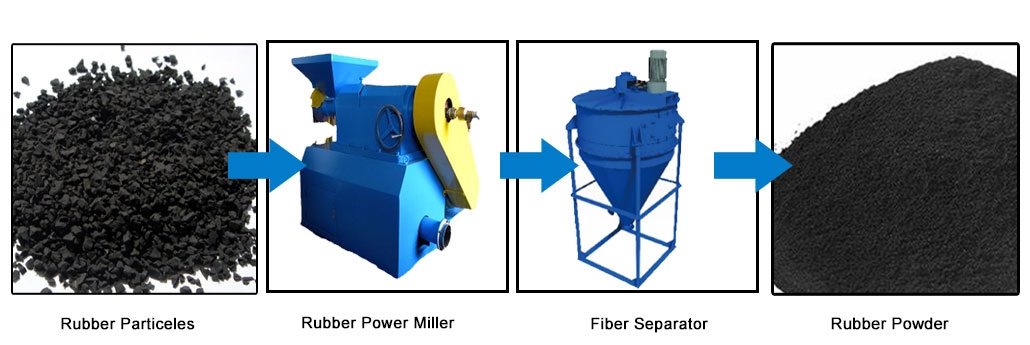

- Rubber Granulation: Remaining rubber pieces are ground into granules or powder using granulators/pulverizers. Fineness is controlled via speed and screens.

- Rubber Regeneration (Optional): Granules may undergo processes like pyrolysis or chemical treatment to restore properties.

- Applications: Recycled rubber creates new tires, mats, hoses, or acts as filler/modifier in other materials.

This process efficiently converts waste tires into valuable rubber materials, promoting resource recovery and environmental protection.