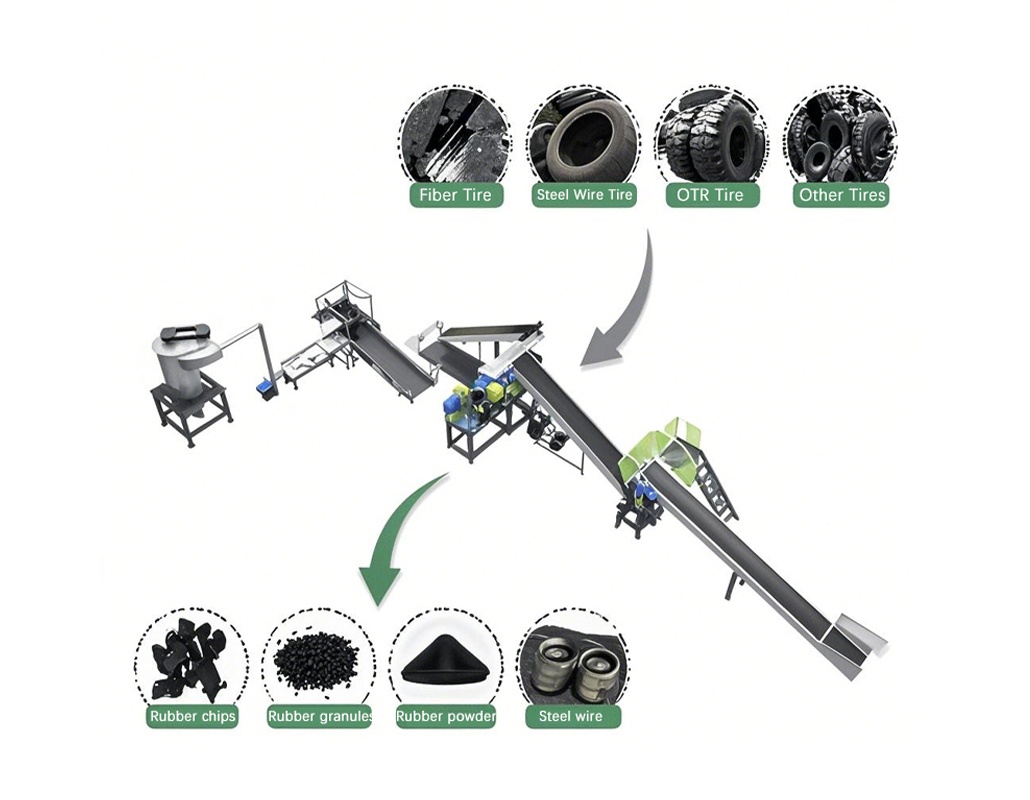

Waste car/truck tires are not useless. On the contrary, they have high economic value. After reasonable recycling, they can be sold at a high price. The economic value of waste tires mainly comes from two parts: one is tire wire, including wheel hub wire and wheel tread wire; the other is tire rubber, which can be processed into rubber blocks, rubber particles and rubber powder, and then made into rubber products.

Working Process:

We have two types of the tires bead wire puller, single puller and double puller.

The tires bead wire puller is used for completely pull out the inner bead wire of the tire at one time. Its purpose is to facilitate subsequent crushing or cutting.

Features:

1. It adopts the integral bottom plate, which is the most efficient wire drawing equipment on the market.

2. It adopts the structure of double transmission and double hooks, which can pull out the steel wires on both sides of the tire at the same time, and the efficiency is 3 times that of the single hook wire drawing machine.

3. Mechanical transmission, and the pull hook adopts a disc structure, which occupies a smaller area.

4.Automatic circuit protection system and a safety protection bracket.

The Tires Shredder is a powerful machine which can crush the steel wire radial tires into rubber blocks of about 50*50mm. It is used to crush and remove waste tires with steel wire rings.

Features:

The blade is shredded by knife, and after subsequent special heat treatment, it has high hardness and high wear resistance, which solves the problem of difficult replacement, difficult repair and high cost of blade wear, effectively improving maintenance time and reducing labor intensity.

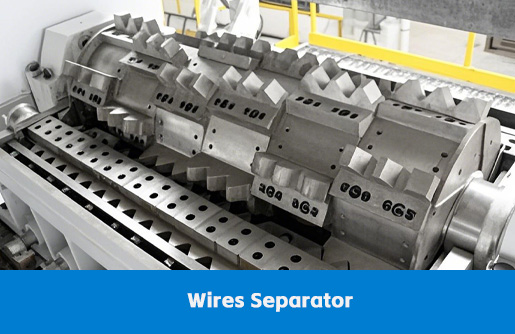

The wires separator is used to tear the tires rubber blocks into particles of about 10-15mm.

Due to the special design and special treatment of the moving knife and the fixed knife, the equipment can process tire rubber blocks with a total wire diameter of 30mm and a tire stop wire ring, and the tool life can reach 20,000 tons of tires before replacement. The moving knife can be replaced on both the front and back sides (if the front of the moving knife is worn, the back of the knife body can be transferred to the front and continue to use it). A fixed knife can also be replaced on both the top and bottom sides, and can also be used at 180 degrees. That is to say, a moving knife can be used twice without grinding, and a fixed knife can be used 4 times without grinding, which greatly extends the tool life and reduces the maintenance cost and equipment maintenance cost. Humanized design, maintenance or replacement of knives and screens are all hydraulically opened automatically, effectively improving maintenance time and reducing labor intensity.

It can crush the larger rubber particles of 50*50mm into smaller rubber particles of 1-5mm, and can also produce rubber particles suitable for plastic runways, etc.

Features:

1.Handling capacity :1000- 1200 kg / H

2.Feed size: <50mm*50mm

3.Discharging size :1- 5 mm

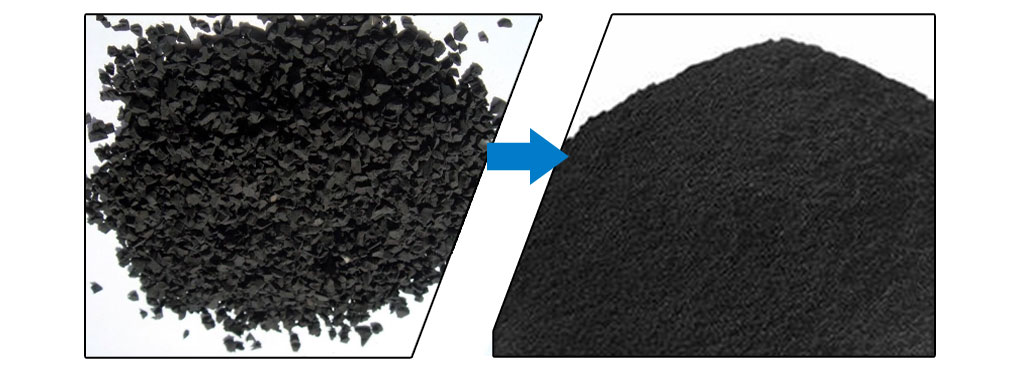

The rubber powder mill is used for further deal with the bigger size of the rubber particles into 1-8mm powder or even smaller below 1mm like 0.5mm.

Fiber separator is used for separate the minor fiber from the rubber particles and powder to collect the clean and pure rubber powder. This process helps to simplify the application of the rubber powder further using.

Application of the Rubber Particles&Powder

日语

日语 English

English Français

Français Русский

Русский Español

Español Português

Português عربي

عربي